Established industries offer oxy cutting services that refers to trimming mild metal that has lower melting point and eliminates the oxidise by forming a protective crust. Experts are well-versed and capable enough to trim according to client’s requirements and provide accurate dimensions for required metals. The procedure includes brazing, welding, heating and hard surfacing that would help to achieve desired outcomes.

Why is it Important to Consult an Expert Metal Supplier?

There is no denying, to the fact that steel plates are resistant to both rust and abrasion as well as provides durability for longer utilisation. Skilled supplier offer different dimensions, grades and thickness depending on client’s requirements. The mechanism of the material is utilised for strengthening and bracing purposes as well as it provides flexibility.

Professionals are knowledgeable and capable enough to advice clients over their concerns and guide them to select appropriate metal suitable according to their requirements. Furthermore, the idea utilisation of this material is for varying industries such as home construction, mining, machinery engineering, shipbuilding and other departments. Well-known companies offer customisation as the material could mould into any specific dimension and shape.

Generally, many renowned companies highly suggest purchasing high quality metal consisting of top trusted brands offering effective outcomes. Moreover, they also offer budget-friendly bundles without compromising on quality of metal.

Benefits of Purchasing Steel from Reputable Company:

Established companies offer wide range of steel products that include plate stock, wear plate, hardox wearparts, high strengthening steel and other metal accessories.

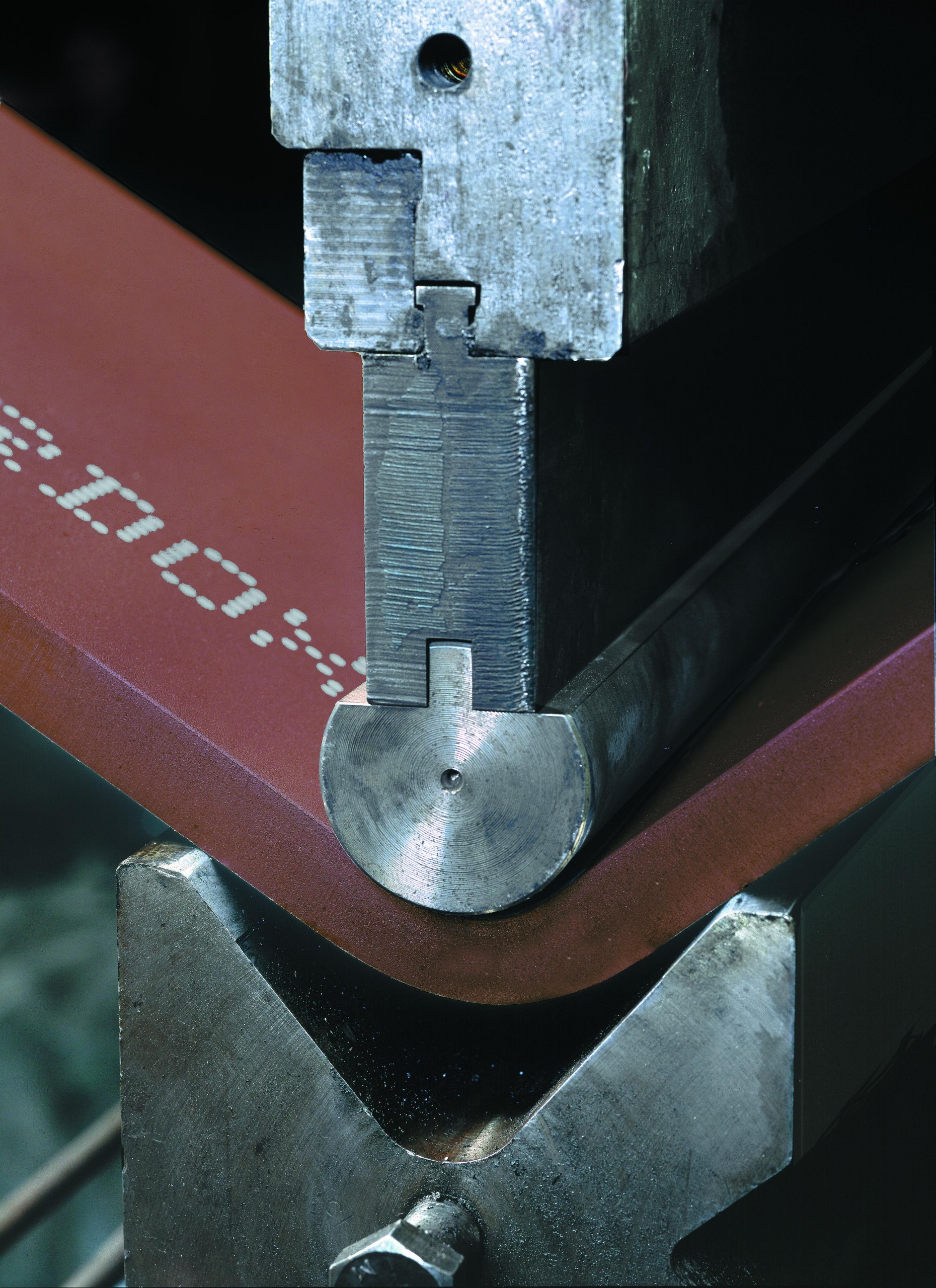

- Experts offer varying services that include cutting, drilling, wash grinding, bevel cutting, folding, rolling and testing.

- Further, they also offer their assistance for machining, welding and other fabrication of steel products suitable according to client’s requirements.

- Expertly curated program also includes heat treatment and plate testing before sending out the product for delivery.

If anyone is looking for purchase of steel products they should enquire with the finest businesses.