One of the most common materials of manufacturing metal products is steel plates, popularly known as flat steel. The concerned item is usually produced to varying thicknesses, widths, and welded together for creating the final product. High-carbon and stainless steel are the two variants that are commonly available in the market.

The uniqueness of Steel Plates

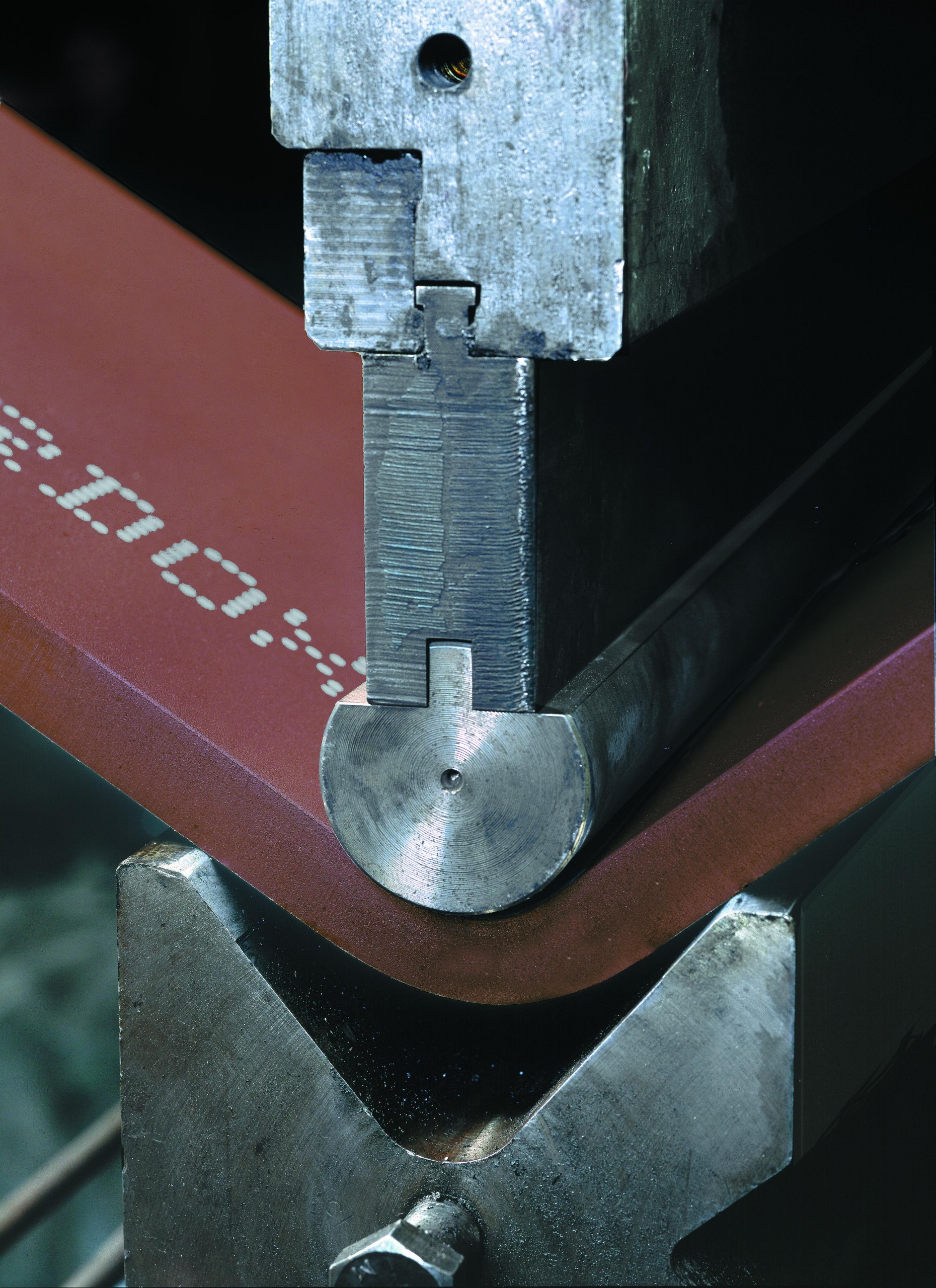

Experienced and skilled steel suppliers in Melbourne propagate that high-temperature steel was rolled into sheets and it is the primary raw material that gained its strength. Established manufacturers compress layer after layer of steel and forge it into a single steel piece until adequate and proper dimensions are achieved. With the cooling of the flat sheet, it hardens to form a usable piece of product. The variant of the manufactured product depends on the ingredients used for producing the molten steel.

Structured steel is essentially a common plate grade. These variants are often used for manufacturing reinforcing plates and building girders. The concerned product gets attached to a concrete foundation with anchor bolts that are often deployed for anchoring steel beams. The latter is usually welded or bolted to plates for creating a rigid foundation on which the construction is built. Such an effort spreads out the load of the building across the entire width of the plate.

The popularity of Steel Plates

Low-carbon steel is the most structural-grade plate. It enables the plate to be drilled and manufactured as required for fitting all construction requirements. These products are often used for the production of heavy equipment pieces, such as bulldozer chassis and earthmover booms. Armor plate, bullet-proof and marine grades are few other specialized plate steel grades.

Industry professionals recommend using the correct type of flat steel for matching it effectively with the job. Low-carbon structural grade plates do not go well with a ship manufacturing process. Instead, a marine-grade should be used for the same as it is resistant to corrosion and rust. Contact professionals for the best quality steel plate material.